DEVELOPMENT, PROTOTYPE MANUFACTURING, AND TESTING OF A NEW GENERATION AXIAL (ACTION) FAN COMPLYING WITH ERP REGULATIONS

- Researcher: Prof. Dr. Tahsin Engin

- Supporting Organization: TUBITAK TEYDEP 1505 Program / BVN Ventilation Systems & Electric Motors / Istanbul

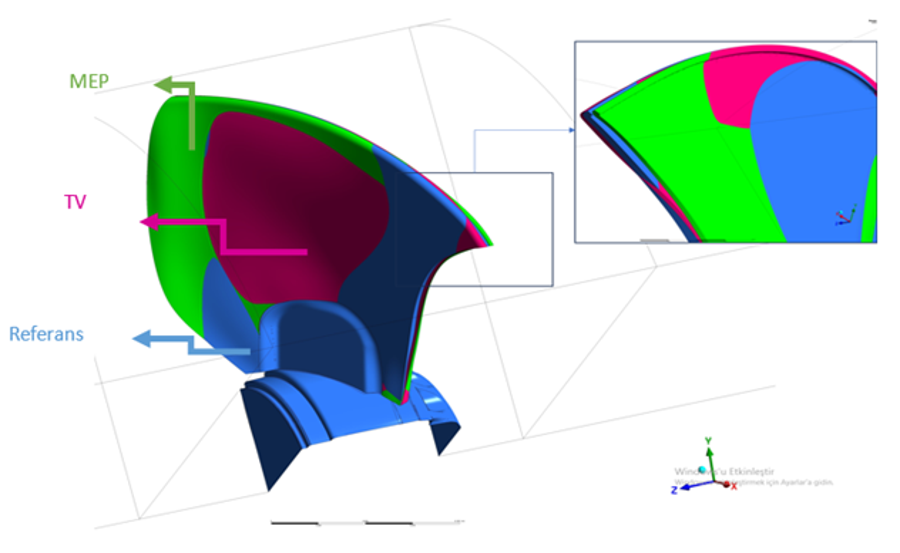

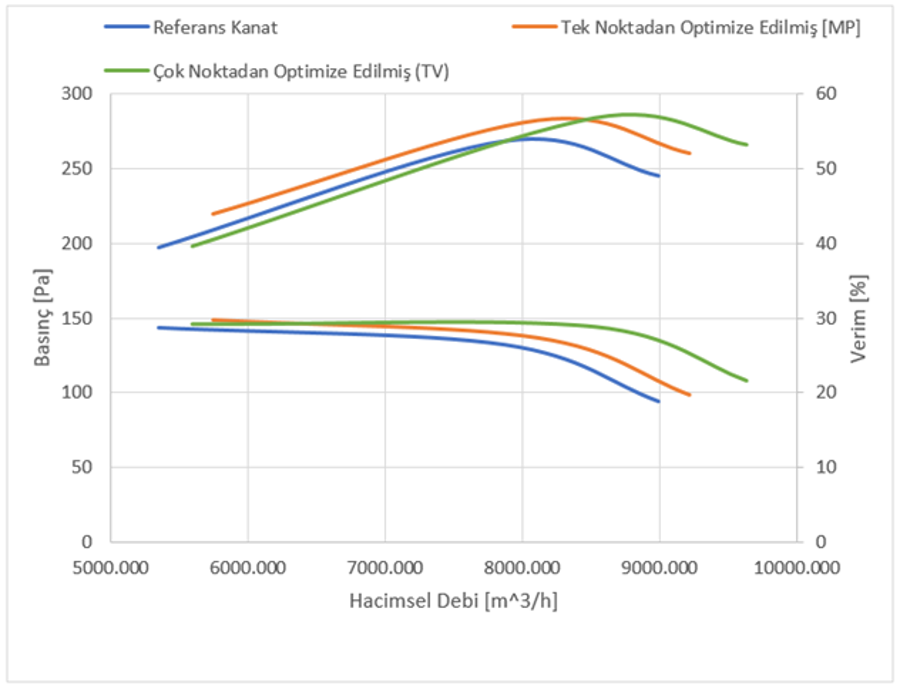

Abstract: Regulations such as ERP, in which our country is involved, aim to reduce carbon emissions by 20% by 2035. Fans supplied by all countries involved in the agreement must comply with this regulation. In response to intense demand from customers, the project aims to develop an axial fan with a 500 mm diameter and 8300 m³/h flow rate, operating under 60 Pa static pressure, using two optimization tools: RSO and Adjoint. The developed fan will be at least 3-4% more efficient and 30-40% cheaper than existing models. The goal is to provide an import substitution for axial fans and establish a presence in the international market through the advantages it provides.

OPTIMIZATION OF SEPARATOR TANK USED IN OIL-INJECTED ROTARY COMPRESSORS, DEVELOPMENT OF DESIGN METHODOLOGY, PROTOTYPE MANUFACTURING, AND TESTING

- Academic Advisor: Prof. Dr. Tahsin Engin

- Supporting Organization: TUBITAK TEYDEP 1507 Program / Mehmet Özen Makina San. Ve. Tic. A.Ş.

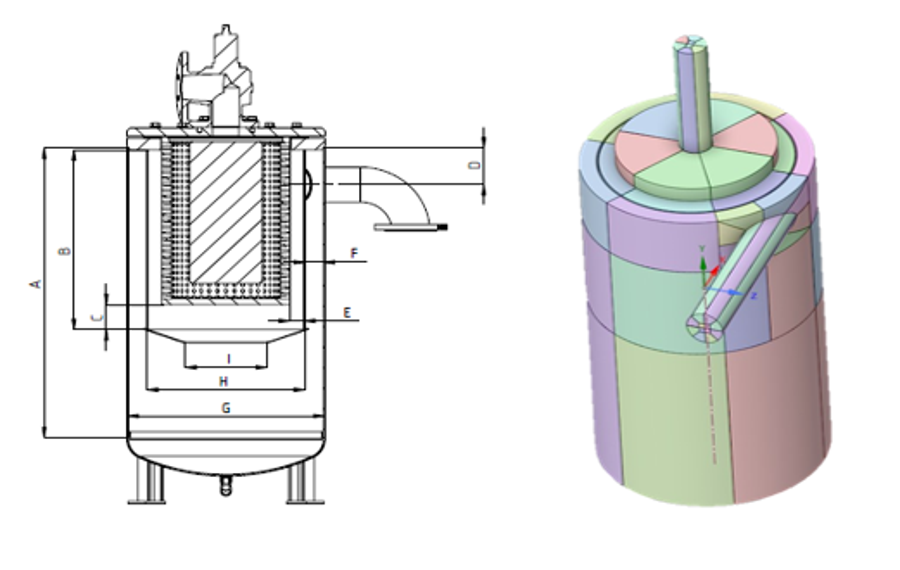

Summary: Cyclonic separators used to separate the oil/air mixture discharged under pressure in oil-injected rotary compressors are the most important components of the compressors. While efficient oil-air separation is expected, minimizing pressure loss is also required. An oil mixture in the pressurized air line causes irreversible problems. Since separator tanks occupy the largest volume in the compressor group, dimensional improvements in this component help make the system more compact. Currently, the separators developed by Özen Compressor are based on experience, but they do not meet customer requirements in terms of performance and size. Especially the oil mixture in the pressurized line remains one of the major issues. This project aims to develop a design methodology and software using Genetic Algorithm-based response surface optimization combined with CFD-based design for separators operating at 7 bar pressure and 29.34 m³/min flow rate. Prototype manufacturing and experimental validation of the reference design are planned. With the developed methodology, optimal design can be achieved within set operating conditions and constraints. A 10-20% reduction in pressure loss and a 4-10% improvement in separation efficiency are targeted compared to the reference designs. The design output is expected to be at least as good as the competitors. The aim is to improve compressor system efficiency and develop competitive cyclonic separators for the international market.

DEVELOPMENT OF A FAN FAMILY FOR COOLING TOWERS

- Academic Advisor: Prof. Dr. Tahsin Engin

- Supporting Organization: Cenk Endüstri Tesisleri İmalat ve Taahhüt A.Ş.

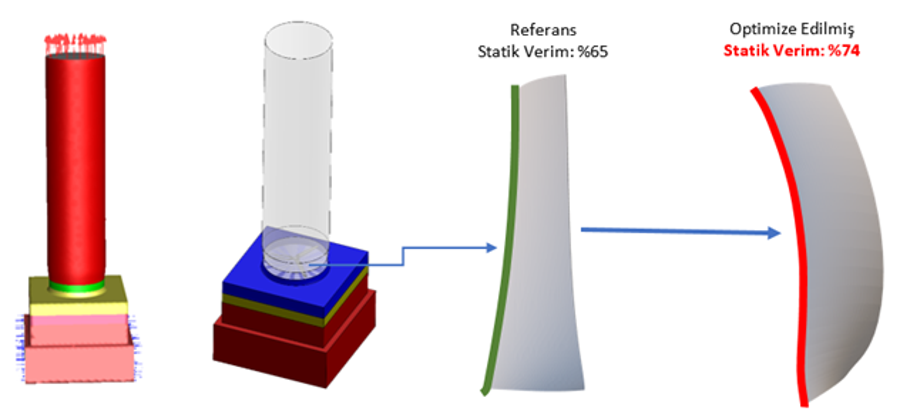

Summary: The project aims to optimize axial fans used in cooling towers using a two-stage optimization tool. An average axial fan represents about 30-50% of the total power consumption of a cooling tower. Therefore, improvements in fan performance will lead to significant energy savings. Additionally, since there is an inverse relationship between fan efficiency and noise levels, quieter fans will be developed. The project will first optimize the blade geometry with a genetic algorithm-based RSM (Response Surface Method) using 17 parameters. Afterward, the optimized blade will undergo free surface optimization using the adjoint solver tool. This will create unique blade geometries independent of mathematical representation and constraints. The blades will be produced by Cenk Endüstri and tested on-site. A 30-40% improvement over existing blade geometries is expected.

ARTIFICIAL INTELLIGENCE-ASSISTED PROCESS MONITORING AND PARAMETER PREDICTION SOFTWARE DEVELOPMENT FOR SELECTIVE LASER MELTING

- Project Leader: Assoc. Prof. Dr. Emrecan Söylemez / ADDPARK İleri Mühendislik Teknolojileri A.Ş.

- Supporting Organization: TEYDEP / ADDPARK İleri Mühendislik Teknolojileri A.Ş.