Developing a Radiant Heating-Cooling

Panel with Phase Change Material Additives to Enhance Energy Efficiency in

Buildings

●

Project Manager: Mir Araştırma ve Geliştirme A.Ş. (Scientific

advisor: Assoc. Prof. Dr. Aliihsan Koca)

●

Organization Supporting the Project: TUBITAK - TEYDEB

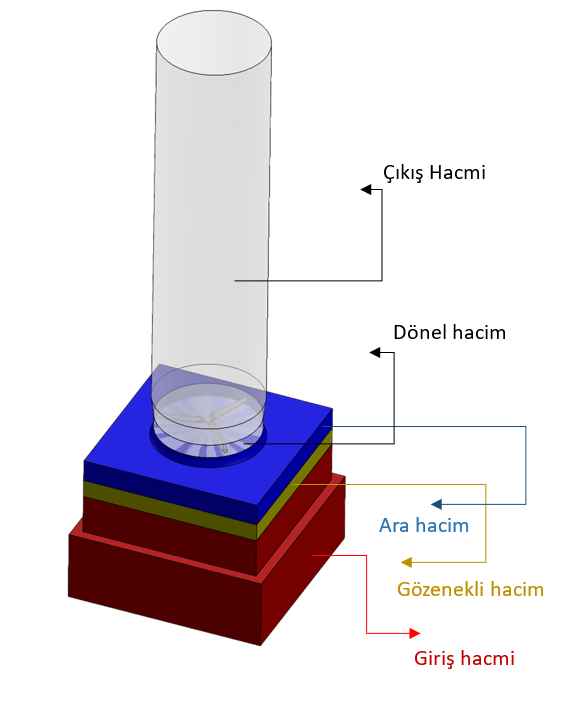

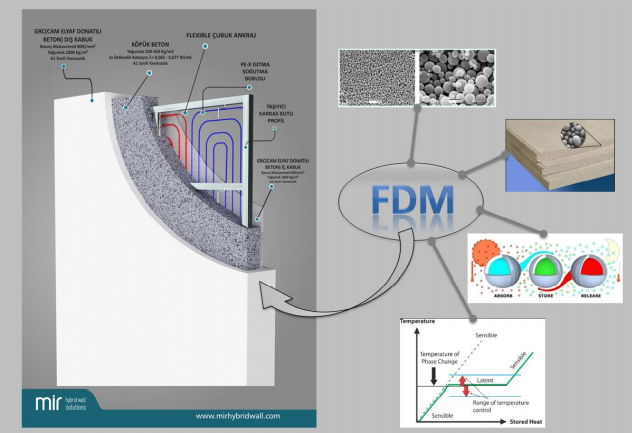

Abstract: The completed industrial research project focused on developing

radiant heating-cooling panels that use phase change material additives. These

panels aim to enhance energy efficiency and thermal comfort in buildings..

Our faculty member,

Assoc. Dr. Aliihsan Koca,

has been appointed on a part-time basis to focus on Technology Transfer,

R&D, and Project Management at TÜSEB – Turkish Health Institutes

Presidency.

The establishment of

the Turkish Health Institutes Presidency (TUSEB) aims to contribute to the

advancement of health science and technologies and promote planned and

sustainable growth, both nationally and globally. It aligns with the objectives

of fulfilling Turkey's demand for cutting-edge technology and innovation in the

realm of health science and technologies, diminishing reliance on foreign

sources, and enhancing and maintaining competitiveness.

DEVELOPING LABORATORY INFRASTRUCTURE

WITH INDUSTRY COLLABORATION

●

Project Manager: Prof. Dr. Seyhan

ONBAŞIOĞLU

- Organization Supporting the Project: Arçelik A.Ş.

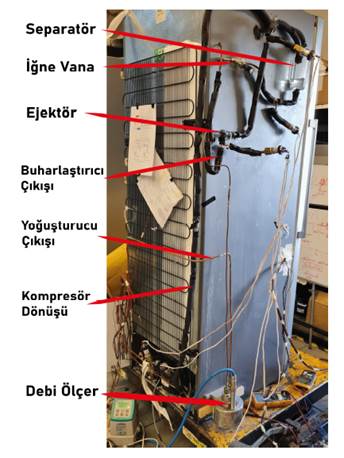

Abstract: The basis of the project

is to conduct academic studies in university-industry cooperation in the field

of "Cooling Systems and Heat Pumps". The main goals are to contribute

to the high technology system design and the sustainable development goals. To

achieve these goals, a test room and data collection system infrastructure will

be established within the laboratory.

Development of Next-Generation

High-Efficiency Axial Fans in Accordance with ERP Standards

●

Project Manager: Prof. Dr. Tahsin Engin

- Organization Supporting the Project: BVN

Ventilation Systems & Electric Motors

Abstract: The subject of the

project is axial fans used for ventilation, drying, heating, cooling, and other

purposes where there is a need for forced air. These fans are essential

equipment in both human life and industry. The electrical consumption of fans

accounts for a significant portion, approximately 16%, of total electricity

consumption. Even small improvements in such high-consumption equipment can

significantly reduce overall electricity consumption.

Within the framework of the Kyoto Protocol, Turkey aims to reduce

carbon emissions by 20% by 2025, following the ERP 2015 standards. However,

with the anticipated new regulations in 2025, there is an expectation for even

higher increases in efficiency. European Union countries do not permit the

import of fans that do not comply with ERP 2015 regulations. In summary, to

participate in the European Union market as per the agreements, it is necessary

to enhance existing fans in compliance with new regulations.

Action fans, unlike conventional fans, require a new fan design

representing distinct operating characteristics for each diameter, without

adhering to fan similarity laws. Each diameter within the fan product family

necessitates a new development process. However, designing action fans based on

fundamental fan design laws and meeting efficiency expectations is nearly

impossible. These fan designs need specific conceptual development and

optimization efforts for improvement, leading to extended development times and

increased costs.

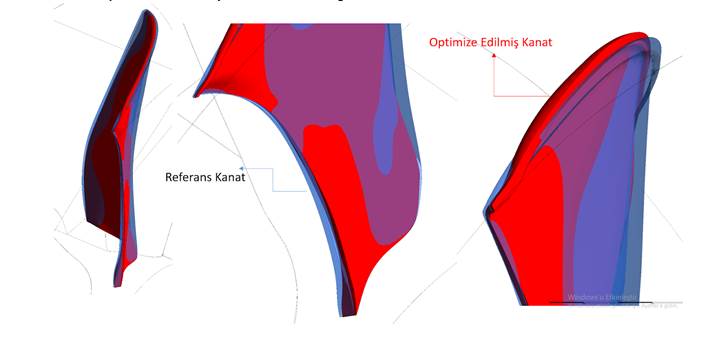

Within the scope of this project, a design set will be created by

parametrically defining all geometric parameters representing action fans. This

set will facilitate a Computational Fluid Dynamics (CFD)-based performance

analysis, enabling the creation of an axial fan design methodology for the

specified diameter.

Development of Dual-Blade

Proprietary Fan and Web-Based Fan Selection Software for Cooling Towers

●

Project Manager: Prof. Dr. Tahsin Engin

- Organization Supporting the Project: Cenk Endüstri Tesisleri İmalat San. Tic. A.Ş.

Abstract: This study focuses on

cooling towers designed to provide cooling water for various purposes in

industrial facilities, utilizing innovative fans developed within the scope of

the project. The dimensions of these structures are determined based on cooling

load and physical constraints. Industrial cooling towers are employed in

natural gas processing facilities, petrochemical plants, oil refineries, and

power plants.

Cooling towers are classified according to heat transfer methods

as wet and dry, based on air passage systems as natural and forced, and based

on structure as packaged and field-erected.

Within this study, a comprehensive optimization of all parameters

of the innovative dual-blade fan will be conducted. An original dual-blade

product family ranging from 14 feet to 34 feet will be optimized for each 2

feet increment using ANSYS RSO and Adjoint solver optimization tools. For this

product family, a CFD-based design methodology will be developed to determine

the blade angle of a fan that can provide the specified diameter, flow rate,

and pressure.