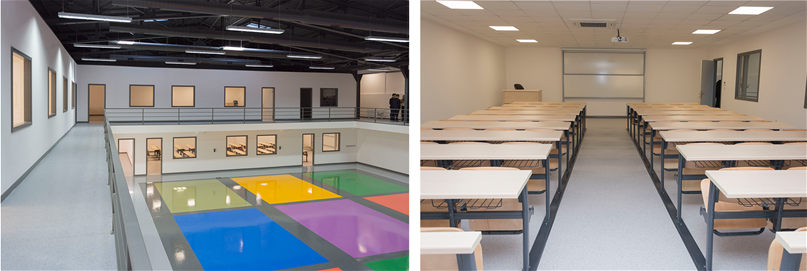

Dr. Keskin Keser has restored the small hall in our faculty's old sports facility, which had long been in disuse, and transformed it into a modern education and research building. Following the restoration efforts, this space was inaugurated as the "Dr. Keskin Keser Education and Research Laboratory" during an opening ceremony held on April 19, 2017. The laboratory provides a well-equipped educational environment where students can conduct their practical lessons.

In the laboratory, experiments are carried out within the scope of mechanical engineering laboratory (MAK-401/MAK-402/MAK-404E) and measurement and evaluation (MAK-312 / İML-325E) courses for the application of theoretical knowledge.

Experiments carried out within the scope of the Mechanical Engineering Laboratory:

1-RADIATOR EXPERIMENT:

This laboratory work is aimed at students understanding the basic heat transfer mechanisms related to the operation of a heater. A mathematical model is created by the students to describe the mathematical relationships between the heating capacity of the radiator and the variables of the radiator capacity and the parameters affecting the capacity.

2- EXPERIMENT ON DRAGING BEHAVIORS OF OBJECTS IN AIR FLOW:

In this experiment, it is aimed to determine the shape that creates the minimum drag force under certain conditions. For the given Reynolds number range, it is expected to measure the resistive forces and to determine the model that disturbs the flow field the least from the models used in the experiment. Also in this experiment, they try to verify your experimental results by comparing them with the theoretical results given in the literature. The problem they will examine is to identify the model with the lowest drag coefficient. Therefore, it is necessary to calculate the resistance coefficients of the models with different shapes in the experiment as a function of the Reynolds number.

3- DIESEL ENGINE EXPERIMENT:

The objectives of this experiment are as follows.

1. To determine the effective torque (Te), average effective pressure (bmep), power (Pe) and specific fuel consumption (bsfc) characters of the engine under full and part load conditions.

2. To determine the volumetric efficiency (ηv) and air-fuel coefficient (λ) parameters of the engine under full and partial load conditions.

3. To determine the thermal power value of the engine (Qe), the heating value to cooling (Qcooling), the thermal value to exhaust (Qexhaust) and the thermal value to friction (Qfriction) parameters.

This experiment is carried out in Maslak-Mob building.

4- SYSTEM RESPONSE ANALYSIS EXPERIMENT:

In this experiment, two parameters expressing the dynamic character of the R-L-C circuit (R: resistor, L: inductor, C: capacitor), which is an electrical vibration system; natural frequency ( ) and damping ratio ( ).

5- BALANCING EXPERIMENT:

It is aimed to find the imbalances that occur on a rotating system in one and two planes, and also to bring it into balance by minimizing the vibration it creates.

6- PRESSURE VESSEL EXPERIMENT:

In this experiment;

• Principal strains and stresses, thin-walled

Experimental determination for pressure vessel.

• It is aimed to determine the factor of safety.

7- DETERMINING FLOW CHARACTERISTICS AND FLOW DISPLAY EXPERIMENT:

The purpose of this experiment is to determine the Reynolds (Re) number, which characterizes various flow phenomena for a flow in a pipe, to display different flow characteristics and to examine the effects of the change of the thermophysical properties of the fluid on the flow characteristics.

8- SERIES AND PARALLEL CONNECTED PUMP EXPERIMENT:

The purpose of this experiment is to understand the concepts used for pumps and to experimentally determine the characteristic values of two identical centrifugal pumps when they are connected separately, in series and in parallel.

9- Indoor Acoustics Experiment:

In this experiment, indoor noise levels in living and working areas increase rapidly with the number of devices used. For this reason, designs that will reduce ambient noise gain importance in terms of comfort.

Acoustic features can often remain in the background when designing interiors. However, the solutions to be applied later can be preferred in order to reduce the noises to reasonable levels. For this reason, it is aimed to reduce the amount of noise in a room with a single noise source by using cubes covered with acoustic materials.

10- DC Motor Position and Speed Control Experiment with PID:

In this experiment, a DC motor will be modeled and the position and speed control of this motor will be studied, and the PID controller, which is widely used in the industry today, will be used for both position and speed control application.

11- Experimental Determination of Vehicle Center of Gravity and Headshot Inertia Experiment:

In this experiment, it was aimed to determine the position of the vehicle's center of gravity and to determine the head impact moment of inertia. This experiment is carried out in Maslak Mob building.

12- Experiment for Determination of Pipe Friction Loss and Local Losses with a Closed Pump System:

The aims of this experiment are;

-1. In turbulent channel flows, the friction of the pipe according to the Reynolds number

Experimental analysis of the coefficient () and obtained a limited part of the Moody diagram.

to be made.

-2. Learning more about fittings and flowmeters (terrestrial

pressure losses) and experimentally calculate the local loss coefficients.

form of calculation.

Experiments Performed within the Scope of Measurement and Evaluation:

1- Automatic Control Experiment:

The aim of this experiment is to provide general information about operational amplifiers and to be recognized on the circuit, as well as to gain practice and skill in various measuring instruments.

2-Arduino Experiments:

In this experiment, it is aimed to master the basic arduino usage skills, to code and to build circuits.

3-Temperature Measurement Experiment:

The purpose of this measurement experiment is to measure the temperature with different methods, to determine the differences between these methods, to observe the errors caused by incorrect connection in temperature measurements with thermoelements.

4-Pitot-Static Tube Determination of Pressure and Velocity Distribution Experiment:

The purpose of the experiment; It is the determination of velocity, static pressure (Ps) and total pressure (Pt) distribution along the convergent-divergent channel with a constant width, using a Pitot-static tube.

5- Vibration Test:

It contains two experiments.

- Undamped Free Vibration Test:

Undamped free vibration, for example, observing the effects of stiffness and mass properties of the system on the natural frequency in the beam-spring arrangement and determining the mass moment of inertia of the system based on the natural frequency measurement,

- Undamped Forced Vibration Test:

The purpose of this experiment is called forced vibration movement, which occurs under the effect of a time-varying driving force. In the experimental setup, the variation of the undamped forced vibration amplitude with one degree of freedom depending on the frequency of the harmonic force applied to the system will be observed.

6-Torsion Test:

In this experiment, it is aimed to experimentally determine the shear stresses with torsional effects and to compare the values found with the shear stress values calculated with theoretical information.

We commerate the late Dr. Keskin Keser and express our endless thanks for his contributions.