Development of Autonomous Delivery System with Hybrid Unmanned Aerial Vehicle

- Project Coordinator: Prof. Dr. Erdinç Altuğ

- Organization Supporting the Project: TÜBİTAK

Abstract: Unmanned aerial vehicles (UAVs), which entered our lives in the last quarter of the 20th century, have started to prove themselves in tasks that will have positive effects on our daily lives, leaving their existence in the field of hobby-entertainment, especially in recent years. It has been seen that they can be useful in many tasks such as detecting and responding to fire, finding survivors, technical inspection of structures and damage assessment, border security, emergency assistance and cargo delivery. It can be expected that these systems will contribute more to our daily lives in the future. The increase in population and density caused by rapid urbanization in the logistics sector, as well as increasing e-commerce and market deliveries, cause difficulties in meeting the increasing demand in the sector and low delivery efficiency. Especially during the pandemic period, the need for delivery methods that do not require human presence has emerged. Especially in the city, by taking a certain part of the traffic from the land to the air, a great relief can be created in the logistics sector by reducing the problems such as traffic density and increase in delivery time.

In the literature, there are many studies and various successful examples of cargo delivery with UAV systems. In this project, it is aimed to eliminate some of the deficiencies of these systems, such as the landing and take-off requirement and the requirement for single package delivery. A hybrid aircraft capable of both vertical take-off and landing with fixed wing features was designed and produced by rapid prototyping methods. This aircraft, which has the capacity to carry multiple packages, is in the UAV1 category. The mathematical model of the aircraft was created and the necessary controller structures were developed. Two prototypes were produced from smart package systems. It has been confirmed that the proposed system and control algorithms are successful through simulations and various experiments of the designed and manufactured systems. This study is one of the first projects in its field in Turkey: The feasibility study and first trials of the proposed system were made. The feedbacks received from different stakeholders show that the proposed system can meet the needs in many areas and be commercially successful.

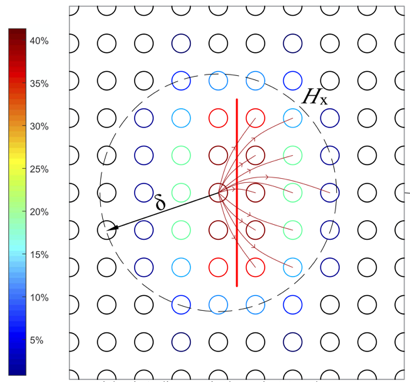

Modelling and Analysis of Fracture Behaviours of Functionally Graded Materials Under Impact Load using Peridynamics

- Project Coordinator: Dr. Adem Candaş

- Organization Supporting the Project: TÜBİTAK 2219

Abstract:

Modelling studies were made to understand the dynamic fracture behaviour of functionally graded materials (FGMs) using Peridynamics theory (PD). Previous studies show that the crack propagation velocity has been affected by the material properties gradation in FGMs. Here, we used a state of art method, state-based Peridynamics to investigate FGMs under dynamic loading conditions with observing the effect of micro-cracks in the material

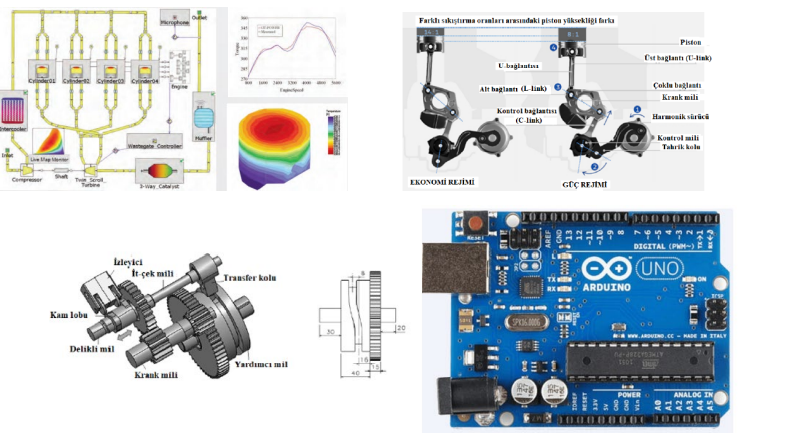

Investigation of the combination of stroke volume modulation and Atkinson cycle strategies in spark ignition engines: A Design, Experimental and Numerical study

- Project Coordinator: Dr. Öğr. Üyesi Barış

Doğru

- Organization Supporting the Project: TÜBİTAK 3501

Abstract: High gas exchange losses and low volumetric efficiency are the main problems effective on fuel consumption and pollutant emissions under urban traffic conditions of spark ignition (SI) engines in which load is conventionally controlled by throttle valve employed between air filter and intake manifold. Due to less fresh charge requirement and the airflow restriction by closer throttle valve position, SI engines are forced to do much more gas exchange work in addition to less power production under part-load conditions. This issue causes poor combustion quality, insufficient combustion speed, and also unexpected further fuel consumption with regards to excessive low indicated efficiency during power cycle at part-load conditions compared to highload conditions. In addition, road transport emissions are shown the main source of air pollution and aimed to keep under control by several legislations, policies and regulations to ensure a high level environmental protection.

As the power requirement is reduced in low speed conditions such as in city traffic, the engine operates in part load conditions. As the load of gasoline engines decreases, the total efficiency decreases very rapidly. The main reason for this is the increase in throttling losses that occur as a result of load control by the throttle and closing of the throttle in the intake manifold at low loads. As a solution of the problem of partial load efficiency in gasoline engines, the combined effect of mechanical cycle skipping, variable valve timing and variable compression ratio on engine performance and reducing effect on pollutant emissions by combining three of the techniques is the subject of the project.

The first objective of this study is to built up a control-based mathematical engine model by optimizing the input variables of spark ignition (SI) engine throttle angle, ignition timing and injection timing to maximize performance and reduce exhaust emissions. The second objective of this study is to apply a variable valve timing system to the skip cycle mechanism by optimizing the intake and exhaust valve activation. With the addition of this strategy, a significant reduction will be achieved for exhaust pollutants increased by cycle skipping standalone. The third objective of this study is to optimize the skip cycle and the intake valve closure timings and geometric compression ratio of the SI engine in terms of fuel consumption and exhaust pollutants under different partial load conditions. The optimization methodology is based on the balance between the geometric compression ratio increase and the intake valve closing profile delay. Before the transition to hybrid and electric vehicles completely, the "transition process from internal combustion engines to electrification", which will be experienced approximately between 2020-2035, will be a successful practical example in promoting more environmentally friendly and fuel-friendly engine technologies as much as possible.

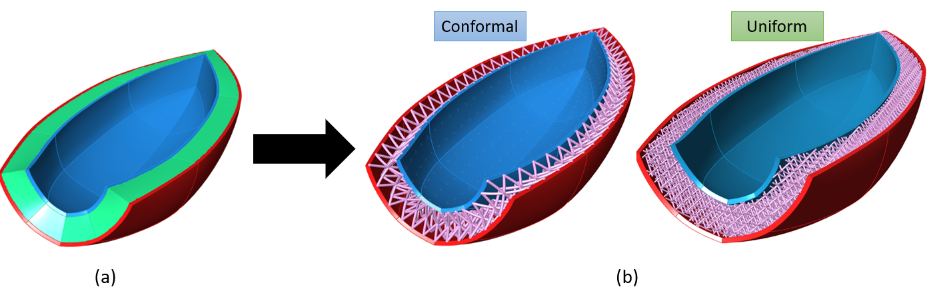

Embedding Lattice Structures into Yacht Hulls and Its Hydrodynamic and Structural Optimization

- Project Coordinator: Assoc. Prof. Dr. Erkan GÜNPINAR

- Organization Supporting the Project: TÜBİTAK

Abstract: Additive manufacturing creates intricate models with complex geometries, not achievable through traditional methods. Embedding lattice structures produces lightweight models with improved structural properties, reducing material use and unit costs. Our project focuses on integrating lattice structures into yacht hulls for lightweight designs, with optimization for structural and hydrodynamic criteria, addressing a unique research objective.

Figure 1 (a) A hull is decomposed into three layers: an outer (in red), an inner (in blue) and a middle layer (in green). (b) The middle layer of the hull is represented with conformal and uniform lattice structures

Proposing New Polyhedral Spline Configurations and Developing Quadrilateral-Dominant Mesh Generation Algorithms for Polyhedral Splines

- Project Coordinator: Doç. Dr. Erkan GÜNPINAR

- Organization Supporting the Project: TÜBİTAK

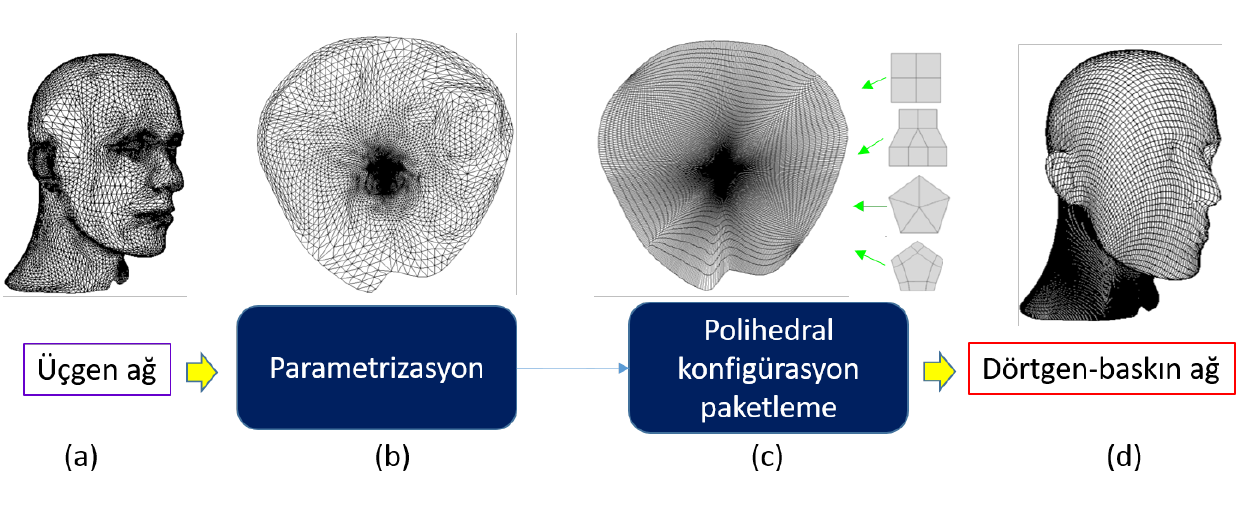

Abstract: Developing B-spline surfaces from point clouds yields quadrilateral surfaces. While B-splines can express quadrilateral solutions, quad-dominant solutions (with fewer elements) pose challenges. Karciauskas and Peters (2019, 2022) introduced polyhedral spline solutions for quad-dominant cases. This study proposes unexplored polyhedral spline configurations, creating spline solutions. An algorithm transforming triangular meshes into quad-dominant ones will be developed, aiming to enhance existing quad-dominant mesh algorithms.

Figure 2 The facial model represented by a triangular mesh (a) will first be parametrized into two dimensions (b) and rearranged on a two-dimensional plane using polyhedral spline configurations, transforming it into a quadrilateral-dominant mesh structure (c). Subsequently, the two-dimensional quadrilateral-dominant mesh will be converted back to three dimensions (d)

Lightweighting and Acoustic Enhancement of Polyester Matrix Glass Fiber Reinforced Composites for the Automotive Sector through Carbon Nanotube and/or Graphene Additives Project

- Project Coordinator: Prof. Dr. Levent TRABZON

- Organization Supporting the Project: TEYDEP - TÜBİTAK

Abstract:

Within the scope of the project, carbon emissions will be reduced by reducing vehicle weights by adapting to the developing technology trends in the automotive industry, and at the same time, acoustic properties will be improved. The thickness of composite parts depends on the number of fiber layers, the inclusion of carbon nano-fillers in the structure will reduce the number of fiber layers, thus reducing the thickness of the prototype part. The use of carbon nano fillers will contribute positively to the sound transmission loss properties of the composite part. The development of sound transmission loss properties increase the comfort features of the car; will affect positively human health.

As a result of the work that will be produced with products that include the targets of our project within the scope of the Green Deal of the EU Council, innovative green composite products with high environmental sensitivity will be produced. The sustainable product production instruction will greatly accelerate our transition to a circular economy model at the national level. The most important part of this transition is the automotive industry. By adding additives to the multi-scale composite part and topology optimization mechanical and acoustic properties will be improved

At the same time, with the increase in acoustic properties and the prototype part gaining significant advantages not only in mechanics but also in many functions, a product with high commercialization potential that the world needs will be produced.

Versatile Agriculture by Fertilizers with QDs Enhanced Nano-composite Hydrogels for Sustainable Food Production

- Project Coordinator: Prof. Dr. Levent TRABZON

- Organization Supporting the Project: Southeast Asia-Europe Joint Funding Scheme for Researh and Innovation

Abstract:

The world's population is expected to reach 9.9 billion people in 2050. Due to rapidly growing population in the world, there will be unprecedented challenges in terms of sustainable food production and growth. Thus, it is extremely critical to find new ways to tackle with such issue in order to compensate any effects of rapid degradation of land and water. Thus, ecological approaches with concern of highly efficient agriculture must be searched and applied by means sustainable alternatives. Nanomaterials were also used as nano- fertilizers, pesticides, or plant growth regulators in agri-biotechnological applications. The influences of the type, particle size, surface charge, and surface modification of nanomaterials on plant growth also have been fully studied. But, the use of quantum dots, QDs, is still an open research area in the agriculture. The main purpose of developing new QDs/nanomaterials in agriculture is to increase plants' growth and yields or reduce the environmental risks from pesticides. it is critical to invent a low-cost, nontoxic, and biodegradable multifunctional hydrogel-based enriched with QDs as fertilizer with both slow- release and water-retention capabilities. In this work, we are planning to develop an innovative economical composite fertilizer technology using biopolymers to entrap QDs as fertilizer agents. The advantages of this approach include increasing crop efficiency, improving soil fertility and reduction of irrigation frequency. Moreover, the fabricated slow- release of QDs integrated hydrogel can be strictly matched with life cycle of the cultivated plants, thus ensuring reduced risk of overdosing and avoidance of environmental issues. Thus, Incorporation of Nitrogen (N), Phosphate (P), Potassium (K) and Si, doped carbon QDs as fertilizer will also be released in a slow-release in addition to other advantages of water retention capacity and aforementioned materials properties. The four universities from three different countries of Turkey, Malaysia and Indonesia will create unprecedented synergy at international level by combining well-matched knowledge and expertise in the field of chemistry, engineering and agriculture. Moreover, the development of the proposed novel system for sustainable food production will be an asset, enhancing the applied scientific knowledge produced by the SouthEast Asian - European scientific community and its international visibility. Morever, the outcomes of proposal with laboratory and field experimental results will provide some innovative and important insights into the sustainable agriculture and food security not only for EU and South Asia but also whole world in terms of agri-biotechnological applications. The technology readiness level will be expected to be TRL-4 and it makes the outcomes of the proposal transferable to market as well.

Wearable Lower Body Exoskeleton System with Flexible Clothing

- Project Coordinator: Assoc. Prof. Dr. İkilem Göcek (Investigator), Öğr. Gör. Dr. Merve Acer Kalafat (Researcher)

- Organization Supporting the Project: TÜBİTAK 1003

(Project no:118E924)

Abstract:

In this project, a new wearable exoskeleton system with flexible clothing has been developed for the use of paraplegics who have lost their lower extremity motor functions due to low back pain, paralysis, and similar disorders. Textile-based strain sensors that can track the user's joint angles and flexible low-profile force sensors that can monitor the loads on the sole of the foot while walking have been produced using the screen printing method. These sensors are designed for use in a rigidly coupled exoskeleton actuated by a series of elastic actuators. As a result of the project, a design was created in which the physical state of the lower body exoskeleton user can be observed through a wearable sensor outfit.

Textile-based Flexible Strain Sensor

Strain sensors used in exoskeleton

Printed Flexible Force Sensors for the feet

TOK 2023 National Automatic Control Conference Hosted by ITU

September 14-16, 2023

The 24th National Automatic Control Conference, presenting the latest developments in strategic areas of control and automation for Turkey, coinciding with the 100th anniversary of the Republic, the 250th anniversary of the establishment of Istanbul Technical University (ITU), and the 65th anniversary of the Turkish National Committee for Automatic Control (TOK), took place under the auspices of Istanbul Technical University.

The symposium was organized as a platform chaired by Prof. Dr. Mehmet Turan Söylemez and Assoc. Prof. Dr. Ali Fuat Ergenç from the Department of Control and Automation Engineering, and Assoc. Prof. Dr. Zeki Yağız Bayraktaroğlu from the Department of Mechanical Engineering. The event featured 154 presented papers, each reviewed by at least two independent referees. Moreover, distinguished figures in the field, such as Prof. Dr. Atilla Bir, Prof. Dr. Frank Allgöwer, Prof. Dr. Maria Prandini, Prof. Dr. Erdal Kayacan, Prof. Dr. Hajime Asama, and (virtually) Prof. Dr. Dang-Il (Dan) Cho, were invited as keynote speakers.

The International Federation of Automatic Control (IFAC), of which the Turkish National Committee for Automatic Control is a national member, provided extensive support for the symposium. In this context, scientists who have served or will serve as IFAC presidents made significant contributions as invited speakers at the symposium. This marked TOK 2023 as the first symposium in history with four IFAC presidents participating as invited speakers.

In this challenging economic period for our country, the symposium's sponsorship by three main sponsors, three gold sponsors, and two silver sponsors underscored the industry's commitment to the symposium's topics and once again demonstrated the strength of our faculty members' industry connections.

Speaking at the opening of the symposium, ITU Rector Prof. Dr. İsmail Koyuncu highlighted that the Turkish National Committee for Automatic Control, founded just a few months after the establishment of IFAC in 1958, was established as the Turkish Automatic Control Society by Prof. Mehmet Münir Ülgür and Prof. Dr. Mehmet Nimet Özdaş. He also emphasized that the Control and Computer Engineering Department, established in 1980 under the Faculty of Electrical and Electronics, has been providing top-level education in control engineering at ITU for 43 years, underscoring its importance for the country and the university.

The gala dinner for the three-day symposium took place on the evening of September 15, 2023, at Istanbul University's Baltalimanı facilities. Additionally, as part of the social program, a boat tour on the Bosphorus and a historical peninsula tour were organized for interested participants.